EDUCATION

2017

Bachelor of Engineering [BE]

Automobile Engineering

Dayananda Sagar College of Engineering

Bangalore, KA. IN.

2019

Master of Technology [MTech]

Automobile Engineering

Manipal Institute of Technology, MAHE

Manipal, KA. IN.

2025*

Doctor of Philosophy [PhD]

MAHE-Deakin Cotutelle PhD

MIT, MAHE, Manipal, KA. IN

Deakin University, Geelong, VIC. AU

*Submitted – Pending Evaluation

Hello,

I am Mirza Faizaan

Dedicated materials researcher with over 5 years of research experience in material extrusion additive manufacturing (MEX-AM), understanding its weathering effects and establishing structure-property relationships through mechanical and material characterisation. I am also passionate about meta-materials and lattice structures for lightweight structural applications. Additionally, I am proficient in CAD and static structural analysis, familiar with ASTM standards for the mechanical characterisation of plastics. My hands-on experience includes working with single and twin-screw extruders, internal mixer, universal testing machines (UTM), and advanced techniques like optical microscopy, micro-CT, XRD, FTIR, and DSC. I also possess skills in analyzing SEM micrographs, image processing using ImageJ and GIMP, and programming in MATLAB for data visualization and analysis. In my spare time, I enjoy 3D printing as a hobby.

EXPERIENCES

PHD RESEARCH EXPERIENCE

My research focused on the optimizing and understanding the overall variance in tensile performance caused by the characteristic process induced voids of the material extrusion based additive manufacturing [MEX-AM], commonly called Fused Deposition Modeling [FDM]. Further, the effects of artificial weathering on MEX-AM poly(lactic) acid was explored in a time-dependent study. The degradation in tensile performance, polymer crystallinity, chemical and thermal characteristics were established over prolonged exposure to UV and relative humidity. Lastly, new frontiers in cellular infill structures were investigated as an alternative to conventional 2D infill patterns with the focused intention to lightweight parts with minimal loss in compressive strength. Here, short fibre reinforcements were looked into as a viable option to improve the MEX-AM PLA composite mechanical properties. However, due to various challenges including poor fibre-matrix adhesion and brittleness of the in-house produced filament, this research project was concluded and may be explored in future.

A study on the overall variance and void architecture on MEX-PLA tensile properties through printing parameter optimisation

Abstract

This study investigates the influence of printing parameters on the tensile properties and void architecture of poly(lactic) acid (PLA) parts fabricated using the fused filament fabrication (FFF) technique. Two Taguchi optimisation methods were employed to identify the optimal parameter combinations for maximising tensile performance. The results revealed a positive correlation between tensile performance and nozzle diameter (ND). Notably, the analysis of the coefficient of variance (COV) studies revealed that both tensile strength and modulus exhibited minimal variation within a tight range of 5.5%, suggesting a high degree of process consistency in achieving desired mechanical properties regardless of the chosen parameters within the investigated range. Micro-computed tomography (micro-CT) analysis was used to quantify void characteristics within the as-printed samples. Micro-CT analysis confirmed the influence of ND and layer thickness (LT) on void architecture. By establishing structure-property relationships, the study revealed that larger NDs paired with finer LTs yielded superior tensile properties due to reduced void content. This work highlights the interplay between printing parameters, void architecture, and the resulting mechanical behaviour of MEX-based PLA parts.

PHD THESIS SUMMARY

-

Submitted: Mirza, F., Baloor Shenoy, S., Nunna, S. et al. Temporal evolution of structure property relationship for UV+RH artificially weathered material extrusion additive manufactured PLA.

-

Mirza, F., Baloor Shenoy, S., Nunna, S. et al. A study on the overall variance and void architecture on MEX-PLA tensile properties through printing parameter optimisation. Scientific Reports (2024). https://doi.org/10.1038/s41598-025-87348-2 [Q1 IF: 4.3]

-

Faizaan, M., Shenoy, S., & Kini, C. R. et al. Impact of Lattice Geometry on Compressive Strength: A Finite Element Analysis. Accepted in conference proceedings at ICCMEH2024, December 2024; Target journal not identified.

-

Won Best Paper Award for paper presented in International Conference on Computational Methods on Engineering & Health Sciences (ICCCMEH2024); December 2024.

-

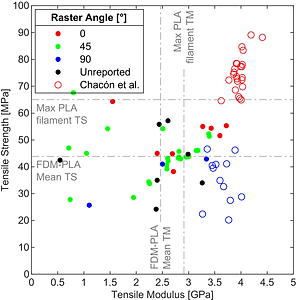

Mirza, F., Baloor Shenoy, S., Nunna, S. et al. Effect of material extrusion process parameters on tensile performance of pristine and discontinuous fibre reinforced PLA composites: A review. Prog Addit Manuf (2024). https://doi.org/10.1007/s40964-024-00825-4 [Q1 IF: 5.6]

-

Faizaan, M., Shenoy, S., & Kini, C. R. (2024). Tensile and Flexural Performance of Hybrid FDM and Compression Moulded PLA/Basalt Biocomposite. In Materials Science Forum (Vol. 1120, pp. 77–84). Trans Tech Publications, Ltd. https://doi.org/10.4028/p-duyo7m [Q4]

-

Poster presented at the IFM Research Conference, Geelong, VIC, AU, titled ‘To what extent do FDM printing parameters really affect PLA tensile performance?’. November 2023.

-

Paper Presented in 3rd International Conference on Advances in Material Sciences 2023 (ICAMS2023); May 2023.

-

Design Patent: “Tensile sample mount for accelerated weathering chamber” bearing design number: 383798-001 Patent and Design Journal, Intellectual property India, India. Award Date: 13 Apr 2023.